Industrial wastewater treatment covers the mechanisms and processes used to treat waters that have been contaminated in some way by anthropogenic industrial or commercial activities prior to its release into the environment or its re-use. Most industries produce some wet waste although recent trends in the developed world have been to minimize such production or recycle such waste within the production process. However, many industries remain dependent on processes that produce wastewaters.

So, industries produce wastewater, otherwise known as effluent, as a bi-product of their production. The effluent contains several pollutants, which can be removed with the help of an effluent treatment plant (ETP). The “clean” water can then be safely discharged into the environment.

Manufacturers face strict regulations on discharge and waste. Non-compliance can lead to expensive fees and operations interference. A wastewater treatment skid will help you:

Planning an Effluent Treatment Plant: Factors to Consider

Certain factories are required by law to install an ETP but deciding what type of ETP to install, what components it should contain and how it is best managed can be quite complicated. This chapter aims to present some simple ideas about treatment plants and offers practical advice on how to choose the most suitable one for a particular factory.

Any factory needing to install an ETP has to consider several factors. For example, information about the wastewater from the factory is required, including quantity and quality. To get this information the factory will have to take samples and have them analysed at a reputable laboratory.

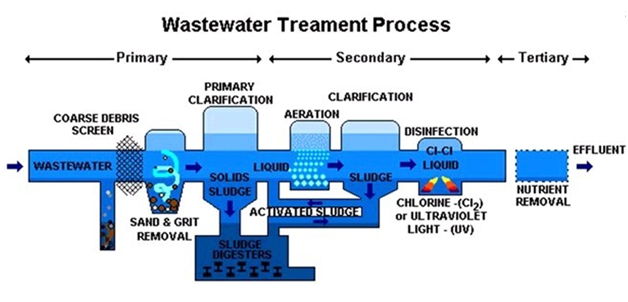

There are many different kinds of sewage treatment plants which vary in the process by which they treat wastewater. Generally, they can be classified into the following types of system:

| Treatment Level | Description | Process |

|---|---|---|

| Preliminary | Removal of large solids such as rags, sticks, grit and grease that may damage equipment or result in operational problems |

Physical |

| Primary | Removal of floating and settleable materials such as suspended solids and organic matter |

Physical and chemical |

| Secondary | Removal of biodegradable organic matter and suspended solids |

Biological and chemical |

| Tertiary/advanced | Removal of residual suspended solids / dissolved solids |

Physical, chemical and biological |